GIDDH Books Revolutionizing Modern Accounting

The world of accounting has evolved, and so have the tools we use. GIDDH Books stands out as a contemporary solution, equipped to handle the challenges of modern-day accounting.

What is Online Invoicing Software? A Guide to Using Invoice Software For Business Success in 2020

Online invoice software is a product that helps business owners automate their invoicing operations. Since the software is

How Can Inventory Management Software Benefit Your Business?

Back in those days when technology hadn’t seeped into our lives, most business owners had to carry huge chunks of paper to manage their inventory.

How to use GST Software Online?

Back in the 90s era, Anu had been running her startup business and managing different aspects of its marketing quite well.

How to Use Accounting Software for Business The Importance of Accounting Software

What is Accounting Software? Accounting systems or accounting software packages are computer applications designed to handle financial tasks and accounts

एकाउंटिंग (Accounting) और बुककीपिंग (bookkeeping) में क्या अंतर है?

किसी भी व्यवसाय संगठन के लिए बुककीपिंग और एकाउंटिंग (बुककीपिंग एंड एकाउंटिंग) की प्रक्रिया अत्यंत महत्वपूर्ण होते है। जहाँ एकाउंटिंग की प्रक्रिया उपयोग किसी कंपनी के वित्तीय रिकॉर्ड, वित्तीय आंकड़ों की व्याख्या, वर्गीकरण, रिपोर्टिंग के

New Dates for Filing GST Returns 2020 What You Should Know

As the Covid-19 pandemic brings the world to a halt,businesses are trying their best to cope up with the economic impacts of the virus. Taking everything into consideration, the government recently announced that the

How Cloud-based Tools are Redefining Businesses During the Pandemic?

There is an old saying Crisis is an opportunity riding on a dangerous wind

Financial Trends in 2020 for Start-ups

Of late, India has emerged as a viable option for startups across the globe. The everlasting success of big e-commerce and retail giants like Amazon,

Business Reporting Tools Turning Data into Information & Information into Insight.

Analysis has never been easier, more productive and immensely profitable with the Giddh Dashboard and its business reporting tools!

Top 5 Trends Revolutionising the Accounting Software

Accounting software is a crucial tool for any business. It helps a business manager run the business with proficiency

10 Features of Online Accounting Software that Lead to Business Growth

With the advent of technology, almost every aspect of business has evolved drastically.Machines and systems have taken over much of the work, that had to be done manually. This has led to greater ease

The State of Indian Financial Accounting Post COVID-19 All You Need to Know

The situation has caused a lot of upheaval in the business world, such that multiple businesses are scrambling to stay

All You Need to Know About the Types of GST in India

Indian constitution had always been imposing tax from the early days of the year 2000. In the initial days, the citizens of India had

Basic Accounting Terms Every Aspiring Accountant Should Know

Basic Functions of Accounting The collection, compilation, and [storage of data] for a business’s financial transaction.

What Is GST Audit - All You Need To Know For A Hassle-free Experience

This is a crucial exercise as the GST taxation regime is dependent on the individual’s honesty and trust, wherein the taxpayer is required to assess his own tax liability.

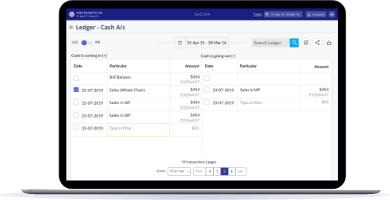

What is General Ledger? A Quick Guide For Businesses

A General Ledger is the building block of financial records for a business. It is used to keep track of all financial transactions within the business and is extremely useful to generate

What is Section 44A All you need to know

While meandering through the income tax filing process and requirements might seem daunting, it is helpful to be aware of the legalities surrounding the income tax act

Desktop accounting software (and its limitations)

The current pandemic is infiltrating our work environments and giving rise to a new normal. This abrupt shift is impacting all spheres and departments of the organizations including the accounting and finance department and they are constantly hosting webinars to deliver traditional services digitally and remotely.

New year planning How to give your business a great start in 2020

For your small business, ending the year the right way can set you up for success come the new year. Use this guide to clean

Year in Review 10 New Awesome Features on the Giddh Software This Year!

Is it an accounting software or an invoice creation software or a sales reporting tool or something you would use for bill generation? Giddh is all that and more! 2019 was an exciting year for Giddh! Here’s looking back at some

11 Simple Money Management Strategies Every Small Business Owner Needs to Know

Excited to have launched your new business? These money management strategies would help you save money on all fronts. If you are a small business owner,

How This Indian Startup Saves Almost 100 Hours with Automated Accounting

Here’s how the accounting team of MSG91, India’s leading cloud-communications startup simplified their accounting with the help of an automated accounting

Best accounting practices for Small and Medium Enterprises SMEs

One of the most important factors to determine the growth and success of a business is its hold on the financial ground. Be it about meeting payment deadlines, managing the cash flow, keeping a track of invoicing or

How can a small business manage HR through accounting software?

Human resources don’t work like any other resource. They cannot be quantified in any way and need a lot of personal orientation. Yet, there are